Automatic coordinate case packing line

Automatic coordinate case packing line,

packing line,

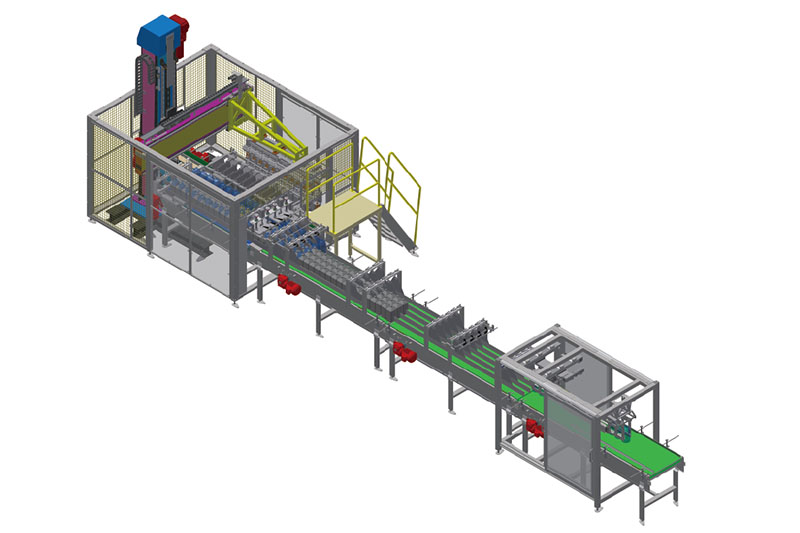

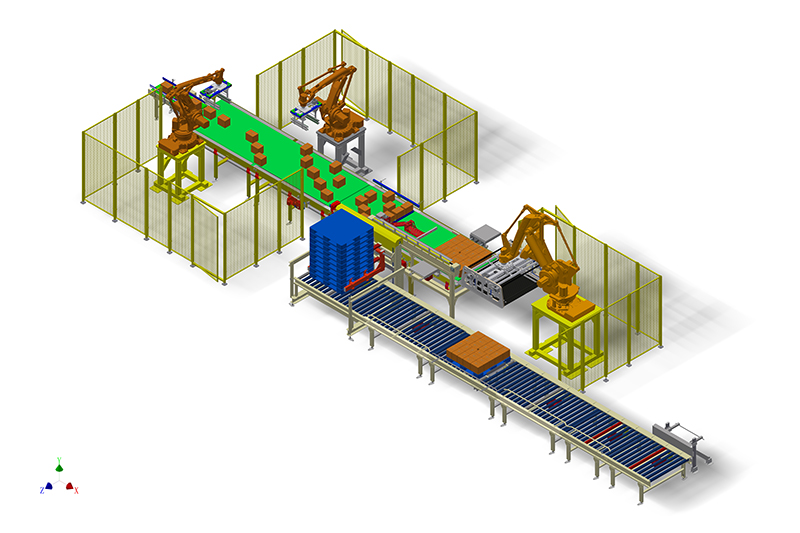

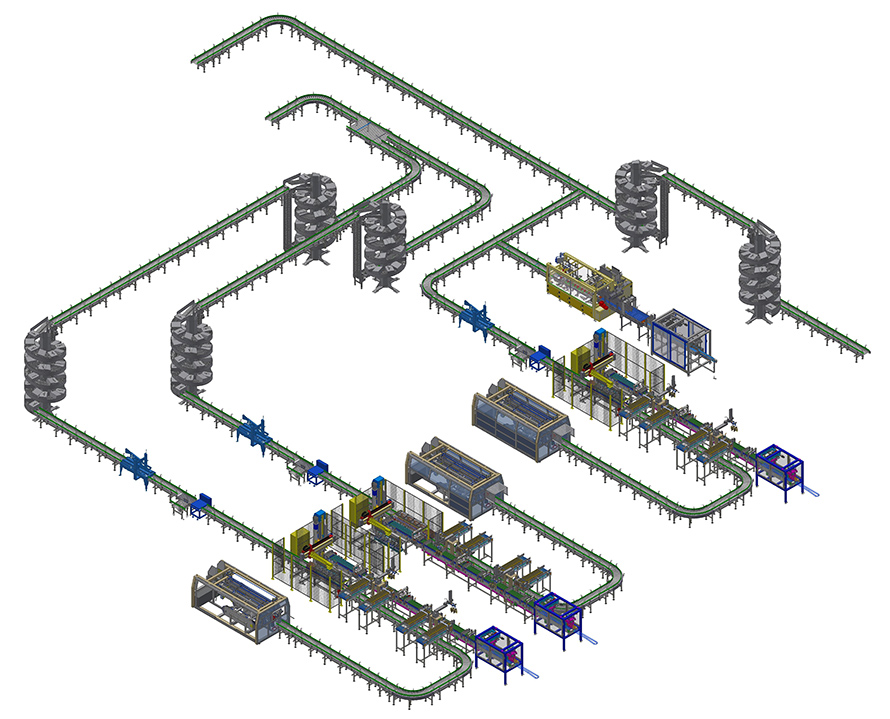

The packaging production line consists of a high-speed divider, a product conveying line, a grabbing conveying line, Hbot, a dual shaft moving mechanism, a box conveying line, a detection mechanism, a cardboard partition gripper, a cardboard partition feeding system, a servo coordinate, a bottle gripper, and a protective fence. The high-speed divider divides the products into multi-lane, while the dual shaft moving mechanism accelerates the passage of products. After the product arrives at the cardboard partition station, the Scar robot loads the cardboard partition into the arranged products. The products arrive at the sorting conveyor. Afterwards, the products are picked by gripper and placed into the cardboard box, and the box conveyor transports the box containing the product out.

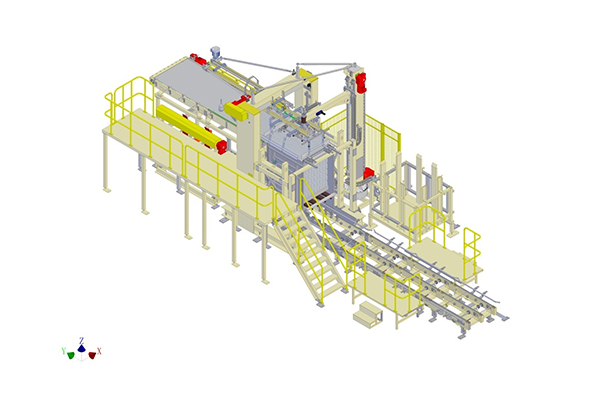

The complete packing system layout

Main configuration

| Robot arm | ABB/KUKA/Fanuc |

| Motor | SEW/Nord/ABB |

| Servo motor | Siemens/Panasonic |

| VFD | Danfoss |

| Photoelectric sensor | SICK |

| Touch screen | Siemens |

| Low voltage apparatus | Schneider |

| Terminal | Phoenix |

| Pneumatic | FESTO/SMC |

| Sucking disc | PIAB |

| Bearing | KF/NSK |

| Vacuum pump | PIAB |

| PLC | Siemens /Schneider |

| HMI | Siemens /Schneider |

| Chain plate/chain | Intralox/rexnord/Regina |

Main structure description

More video shows

- Servo coordinate case packer for glass bottles with cardboard partition

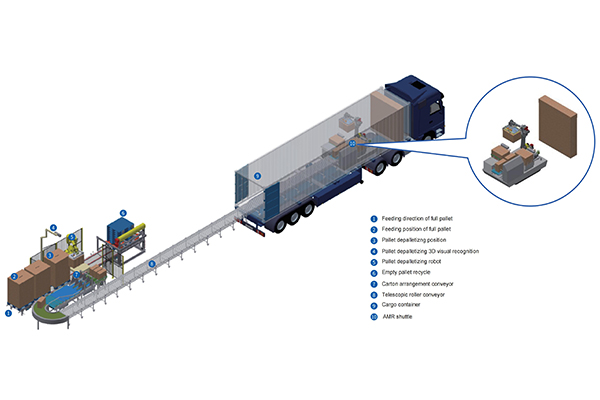

How is the packing machine operated? The products go through a series of automated

and orderly steps, including sorting through the conveying production line, turning to sort, an accelerated buffer, a packing machine, an automatic sealing mechanism, and finally output by the conveying line.