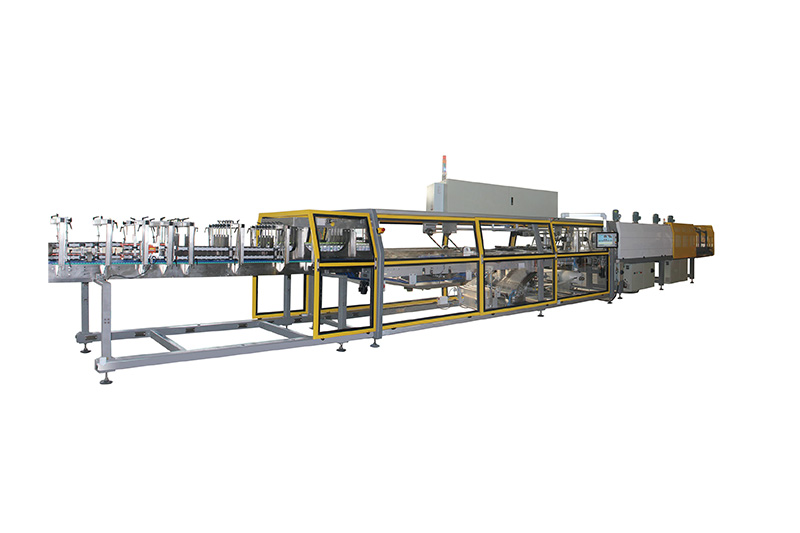

Automatic Retort Basket Loading and Unloading System

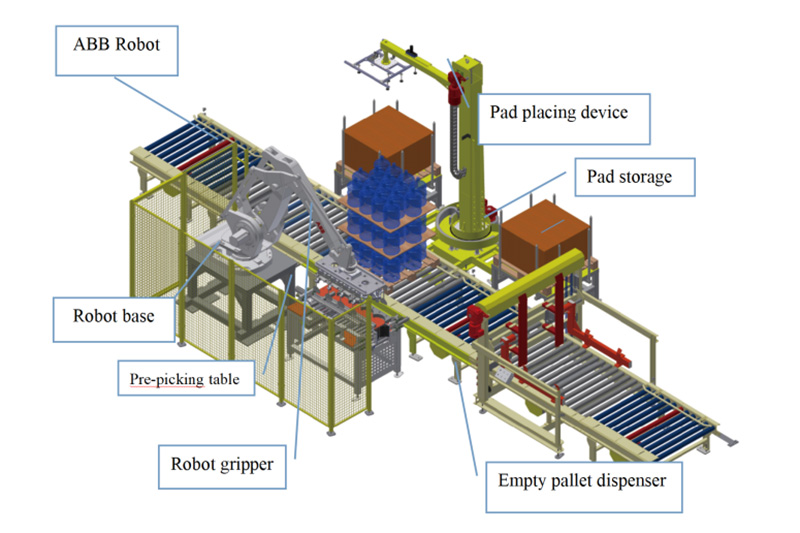

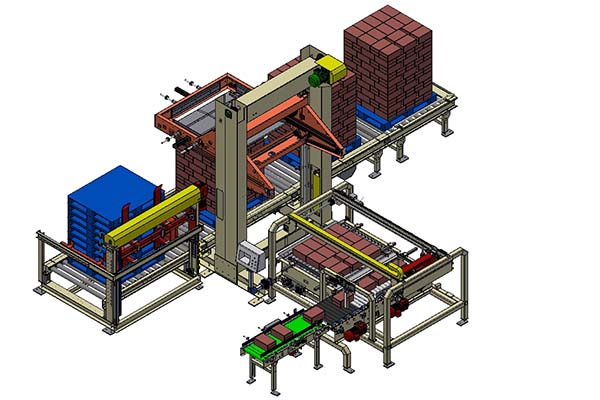

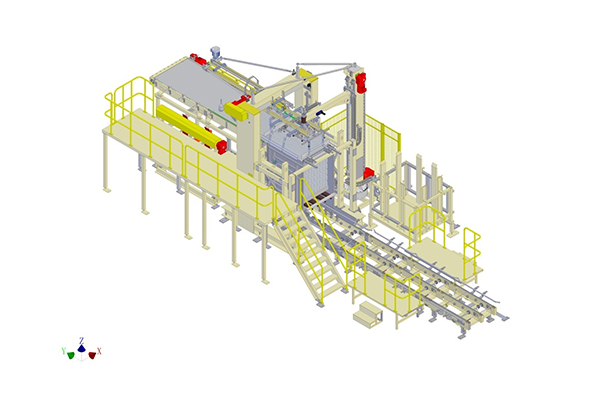

All operations are automatic. The loading and unloading units can be combined enabling the automatic transfer of baskets and layer-pads. At infeed and outfeed, the basket transfer from / to autoclaves can be done by a manual trolley or by automatic systems (shuttles or conveyors).

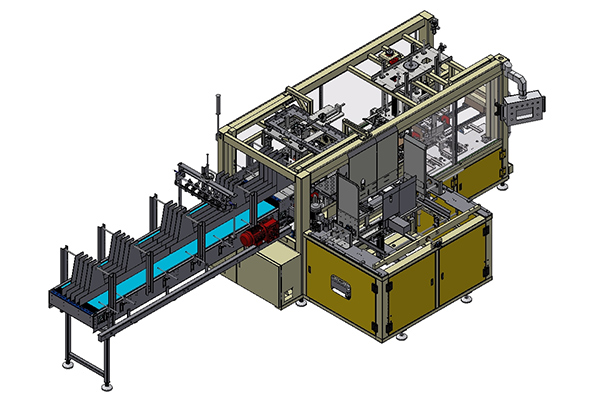

The automatic systems are available in sweep-off version or with magnetic head.

Capacity: over 4 layers / min (depending on basket and container dimensions).

On demand, the lines can be supplied with a supervision system enabling a single operator to control all the operations in real time and act from one control panel.

Working flow

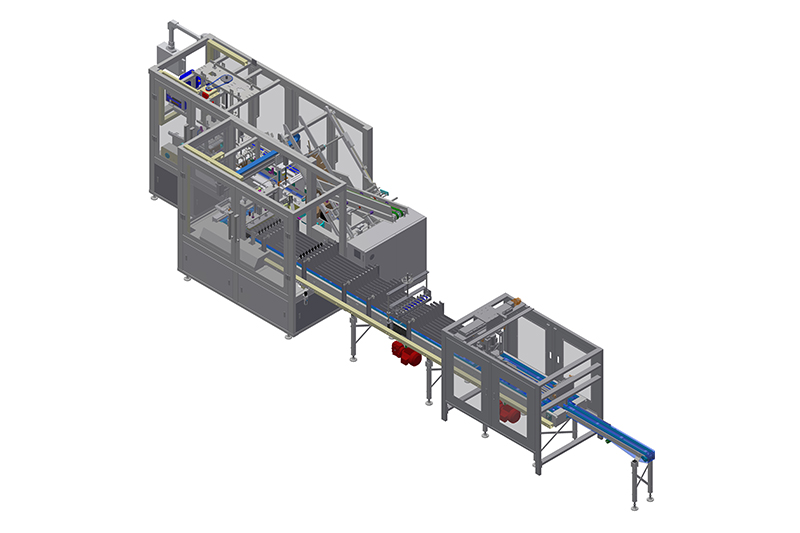

Products are transported to loading machine infeedding conveyor, and products will be arranged automatically on feeding conveyor according to the programmed order, then the clamp will grip complete layer of product and move them to the basket, and then the layer-pad clamp will pick the interlayer pad and place it into the basket which is on the top of products. Repeat above actions, load products layer by layer, once the basket is full, the complete basket will be transported to the autoclaves/retorts by chain conveyor, after sterilization in retort, the basket will be transported to unloading machine by chain conveyor, and the unloading system will clamp the cans layer by layer from the basket to the outfeeding conveyor. The complete process is manless production, which will improve the production efficiency.

Main configuration

|

Item |

Brand and supplier |

|

PLC |

Siemens(Germany) |

|

Frequency converter |

Danfoss (Demark) |

|

Photoelectric sensor |

SICK (Germany) |

|

Servo motor |

INOVANCE/Panasonic |

|

Servo driver |

INOVANCE/Panasonic |

|

Pneumatic components |

FESTO (Germany) |

|

Low-voltage apparatus |

Schneider(FRANCE) |

|

Touch screen |

Siemens (Germany) |

Technical Parameters

| Stack Speed | 400/600/800/1000 cans/bottles per min |

| Height of cans/bottles | According to customer's product |

| Max. carrying capacity /layer | 180Kg |

| Max. carrying capacity /basket | Max 1800kG |

| Max. stack height | According to the retort basket size |

| Installation Power | 48KW |

| Air Pressure | ≥0.6MPa |

| Power | 380V.50Hz , three-phase four-wire |

| Consumption of the Air | 1000L/Min |

| Size of basket conveyor line | According to customer basket |

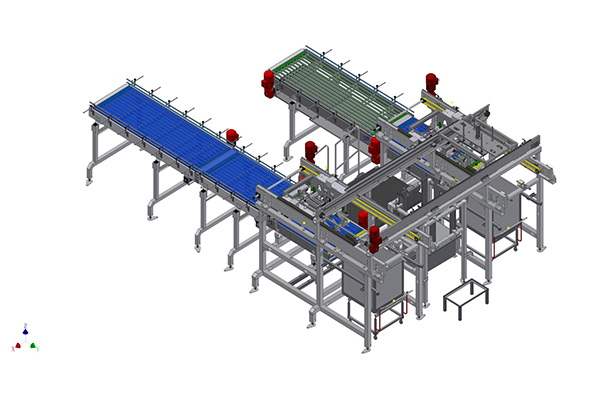

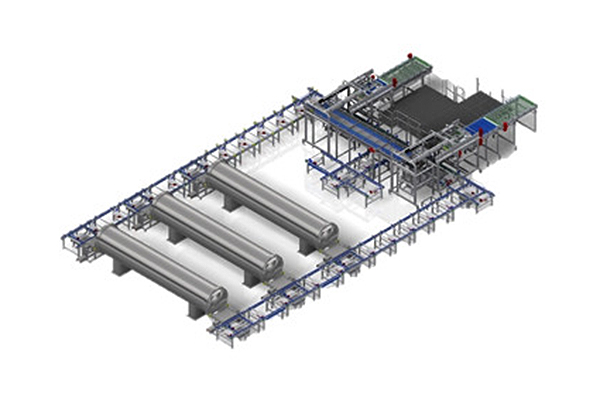

3D LAYOUT

After Sales Protection

- 1. Ensure outstanding quality

- 2. Professional engineers with more than 7 years experience, all in readiness

- 3. Available on-site installation and debugging

- 4. Experienced foreign trade staff to guarantee instant and efficient communication

- 5. Provide lifelong technical support

- 6. Provide operation training if necessary

- 7. Quick response and in-time installation

- 8. Provide professional OEM&ODM service

More video shows

- Full automatic loading and unloading machine for autoclave basket

- loading and unloading machine for autoclave basket

- Loading and unloading machine for retort basket