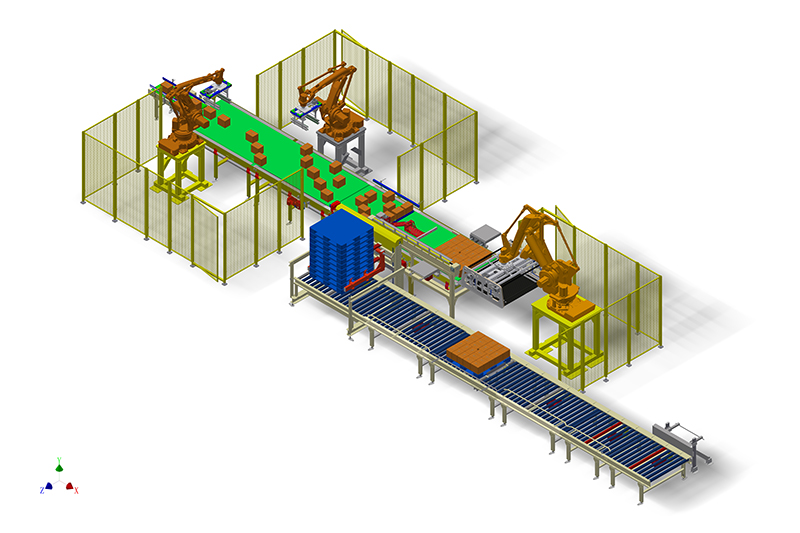

Automatic servo coordinate palletizer

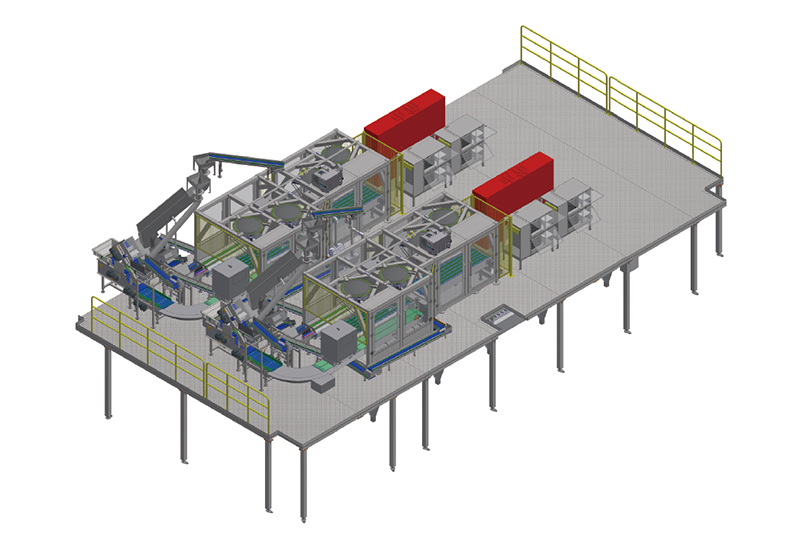

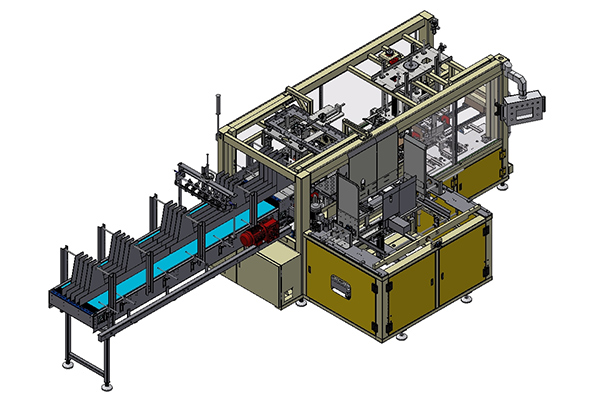

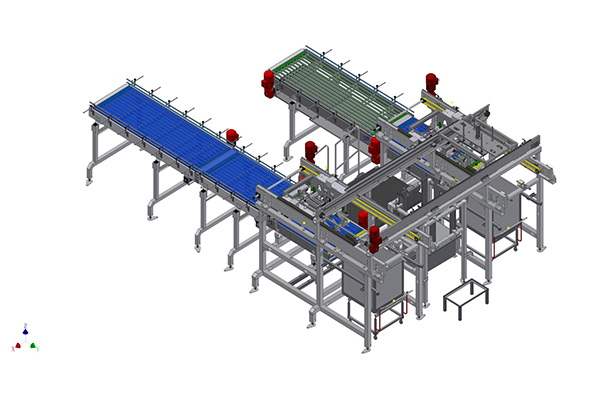

The servo coordinate palletiser has several types; different types are designed according to the customer's configuration requirements: different production speed requirements, different carton combinations on the pallet, different space limits. The whole machine’s operations are handled by the automation system and the machine control in perfect synchronization with the operations performed by the loading head layers, so that the vertical and horizontal movements of the various mechanical assemblies in motion or on the central column follow precise trajectories and coordinates that prevent any contact or interference between them.

Our palletizing solutions allow you to group the most of the three main functions of palletizing: inserting empty pallets, overlapping layers of packs and inserting layer pads between them; offering considerable advantages from the point of view of operational flexibility, job security and maintenance of the machines; concentrating in a well-delimited area the use of forklifts, trans-pallets, etc., optimizing the loading and unloading areas management.

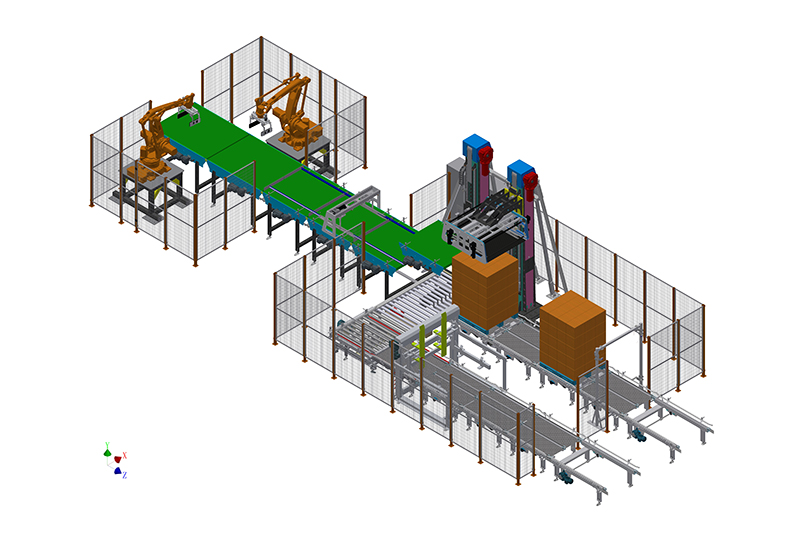

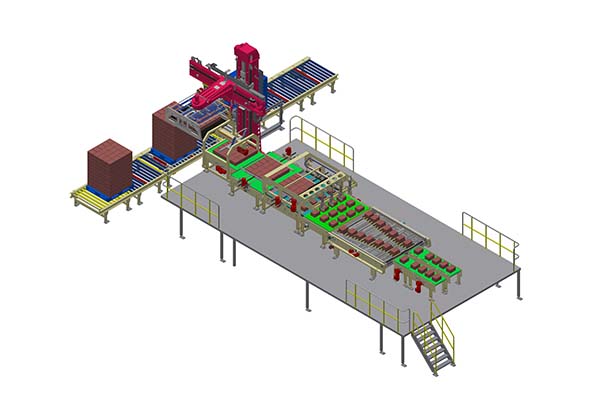

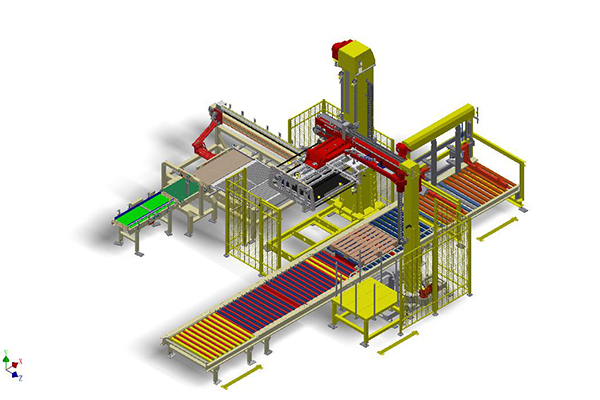

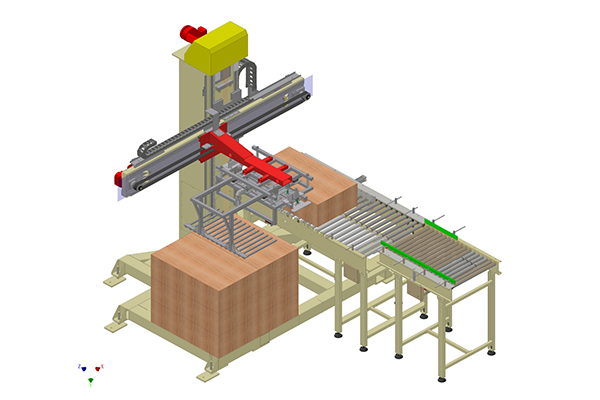

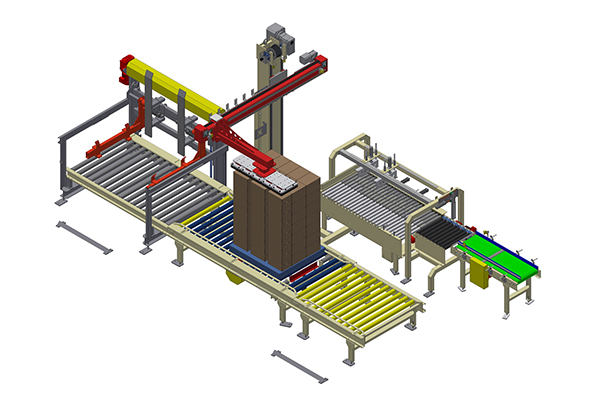

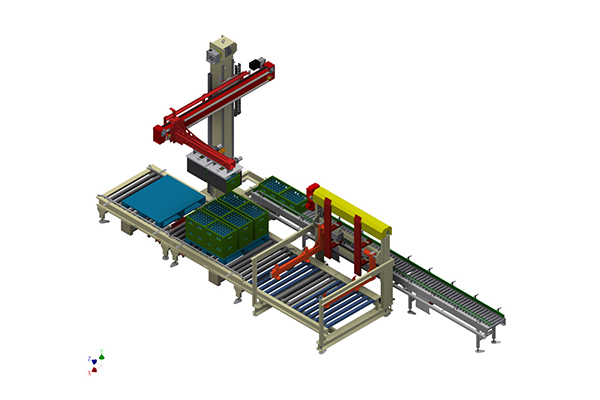

Product Display

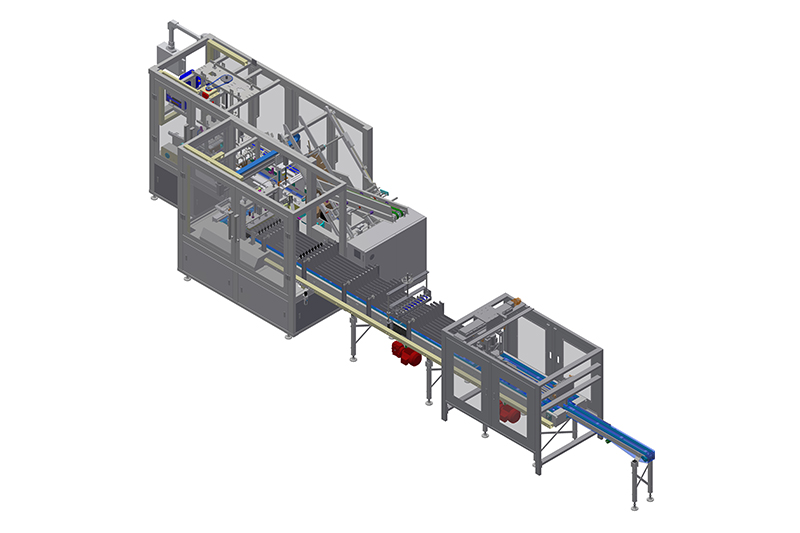

3D Drawing

Single column with double lifting unit and low level infeed (for cartons, film wrapped products and so on)

- Universal, flexible and scalable architecture

- Clean design with advanced ergonomics and accessibility

Single column with double lifting unit and low level infeed (for cartons, film wrapped products and so on)

- Universal, flexible and scalable architecture

- Clean design with advanced ergonomics and accessibility

Electrical Configuration

| PLC | Siemens |

| Frequency Converter | Danfoss |

| Photoelectricity Inductor | SICK |

| Driving Motor | SEW/OMATE |

| Pneumatic Components | FESTO |

| LOW-voltage Apparatus | Schneider |

| Touch Screen | Schneider |

| Servo | Panasonic |

Technical Parameter

| Stacking Speed | 20/40/60/80/120 cartons per minute |

| Max. carrying capacity /layer | 190Kg |

| Max. carrying capacity /pallet | Max 1800kG |

| Max. stack height | 2000mm (Customized) |

| Installation Power | 17KW |

| Air Pressure | ≥0.6MPa |

| Power | 380V.50Hz , three-phase +ground wire |

| Consumption of the Air | 800L/Min |

| Size of the Pallet | According to customer reqirement |

After Sales Protection

- 1. Ensure outstanding quality

- 2. Professional engineers with more than 10 years experience, all in readiness

- 3. Available on-site installation and debugging

- 4.Experienced foreign trade staff to guarantee instant and efficient communication

- 5. Provide lifelong technical support

- 6. Provide operation training if necessary

- 7. Quick response and in-time installation

- 8. Provide professional OEM&ODM service

More video shows

- Full automatic coordinate robot palletizer

- Coordinate robot palletizer for cartons

- Double column type palletizer with robots forming carton pattern

- Fast speed Palletizer for cartons in Nongfu factory

- Fast speed Palletizer for cartons in Nongfu factory