Doypack case packaging line

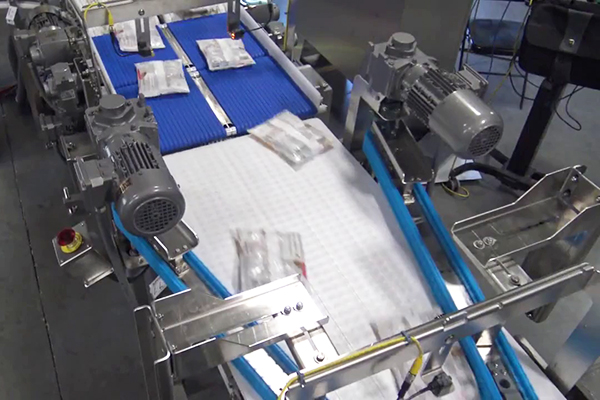

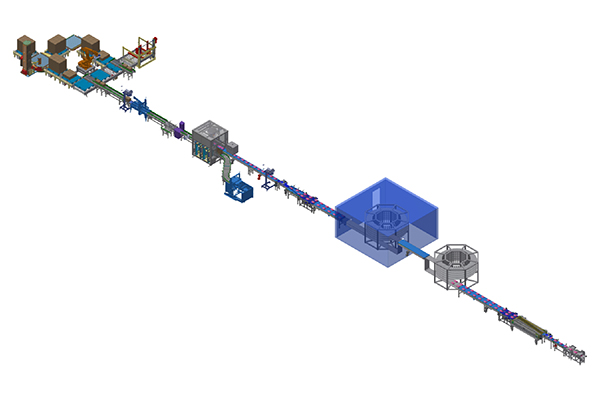

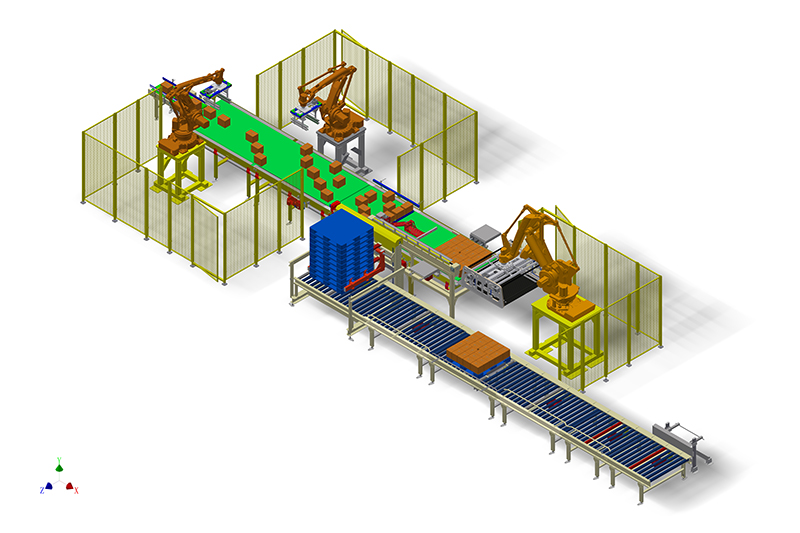

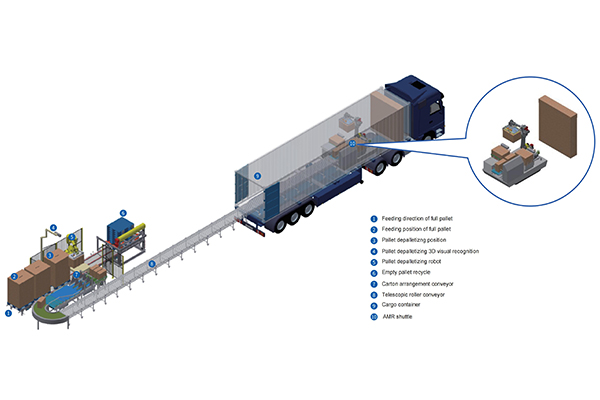

This automatic production line includes the X-ray detector, bags rejector, Bag flatting device, Divider, Bag conveyor, Spiral warmer and cooling, Bag labeling machine, Case erector, Robot case packing system and robot palletizing system.

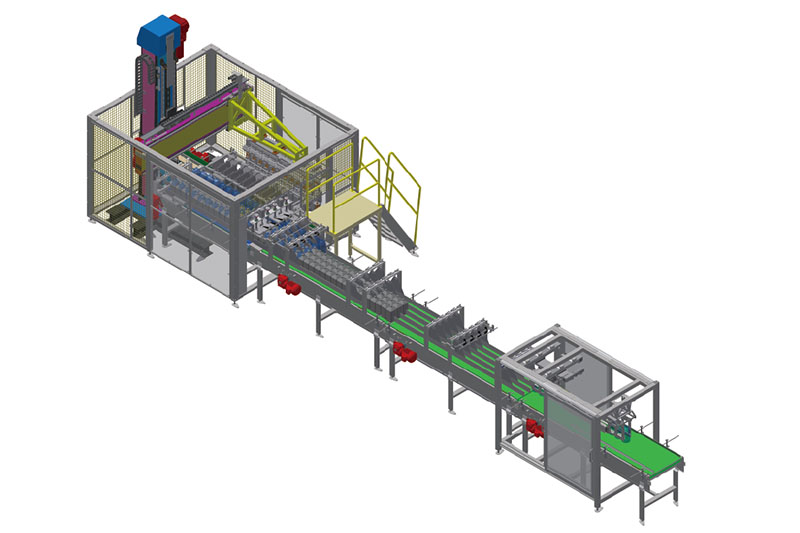

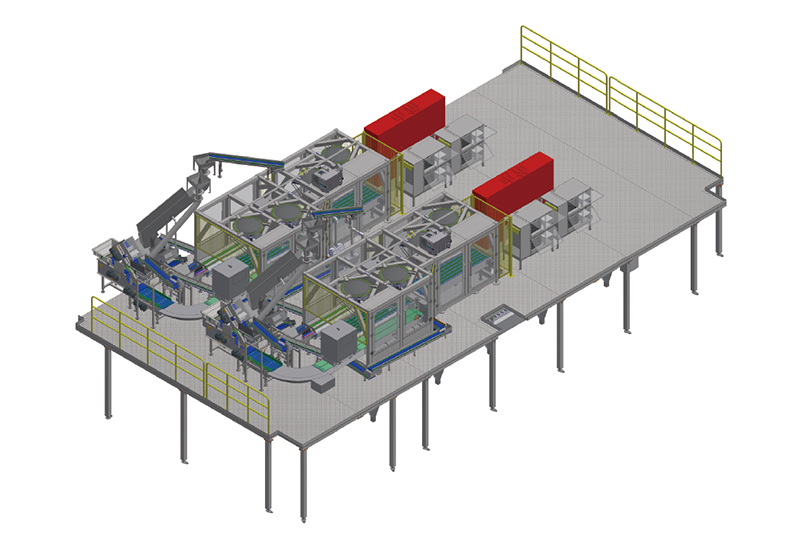

This complete cased food packing line is equipped with Integrated product conveyor line, visual inspection, case conveyor, robotic packing, placing partition mechanism, packing guide structure etc. Packing host machine using spider hand robot + vacuum suction cup gripper to grab products. The product feeding conveyor is equipped with a visual inspection camera to detect the position and angle of the product on the conveyor, and the robot will follow and grab the product. And the spider hand first grabs the product and place it into the packing guide structure, which squeezes a whole layer of product into the whole line before loading it into the case. The device is compatible with the partition board placing device.

The complete packing system layout

Main configuration

| Robot arm | ABB/KUKA/Fanuc |

| Motor | SEW/Nord/ABB |

| Servo motor | Siemens/Panasonic |

| VFD | Danfoss |

| Photoelectric sensor | SICK |

| Touch screen | Siemens |

| Low voltage apparatus | Schneider |

| Terminal | Phoenix |

| Pneumatic | FESTO/SMC |

| Sucking disc | PIAB |

| Bearing | KF/NSK |

| Vacuum pump | PIAB |

| PLC | Siemens /Schneider |

| HMI | Siemens /Schneider |

| Chain plate/chain | Intralox/rexnord/Regina |

Main structure description