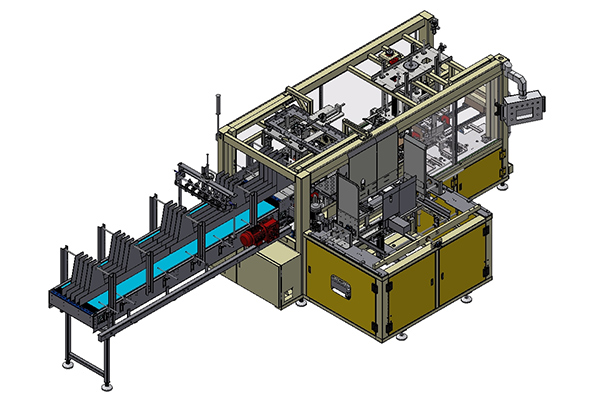

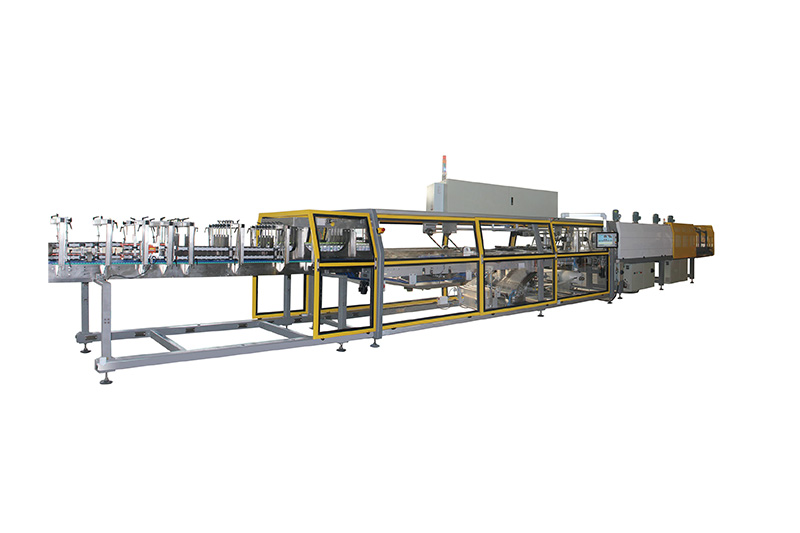

Drop type wraparound case packer

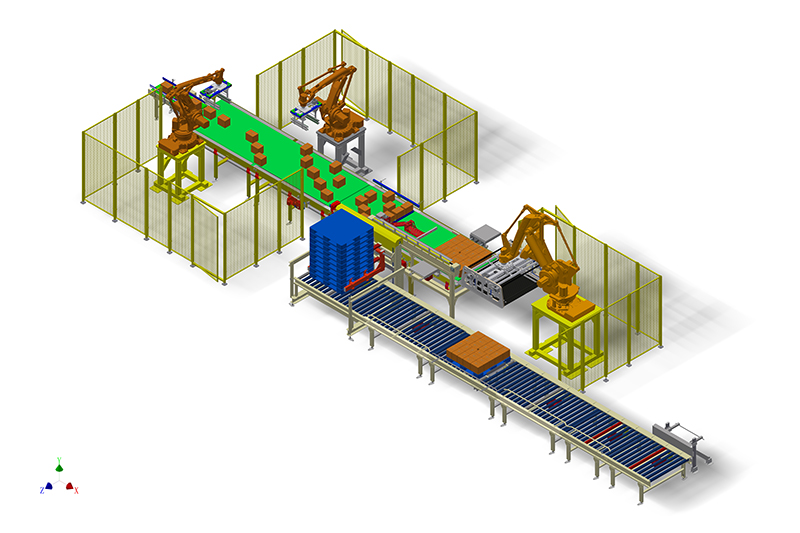

Main configuration

|

Item |

Specification |

|

PLC |

Siemens (Germany) |

|

Frequency converter |

Danfoss (Denmark) |

|

Photoelectric sensor |

SICK (Germany) |

|

Servo motor |

Siemens (Germany) |

|

Pneumatic components |

FESTO (Germany) |

|

Low-voltage apparatus |

Schneider (FRANCE) |

|

Touch screen |

Siemens (Germany) |

|

Glue machine |

Robotech/Nordson |

|

Power |

10KW |

|

Air consumption |

1000L/min |

|

Air pressure |

≥0.6 MPa |

|

Max Speed |

30 Cartons per min |

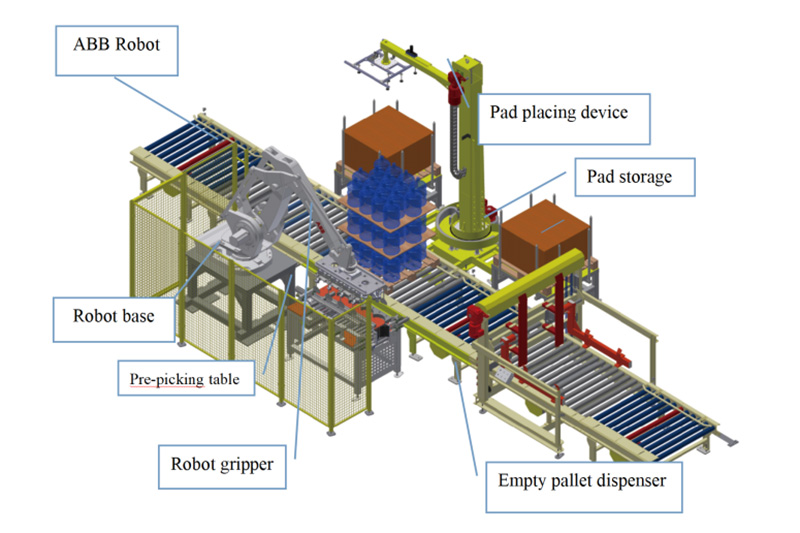

Main structure description

- 1. Conveyor system: the product will be divided and inspected on this conveyor.

- 2. Automatic cardboard supplying system: This equipment is installed in the side of the main machine, which stores the carton cardboards; the vacuumed sucking disk will indraft the cardboard into the guide slot, and then the belt will transport the cardboard into the main machine.

- 3. Automatic bottle dropping system: This system separates the bottles in the carton unit automatically and then drops the bottles automatically.

- 4. Cardboard folding mechanism: the servo driver of this mechanism will drive the chain to fold the cardboard step by step.

- 5. Lateral carton pressing mechanism: the lateral cardboard of the carton be pressed by this mechanism to form the shape.

- 6. Top carton pressing mechanism: The cylinder presses the upper cardboard of the carton after gluing. It is adjustable, so that it can suitable for different size of carton

- 7. Automatic system control cabinet

Case wraparound machines adopt Siemens PLC to control the complete system of the machine.

The interface is Schneider touchscreen with good display of production management and status.

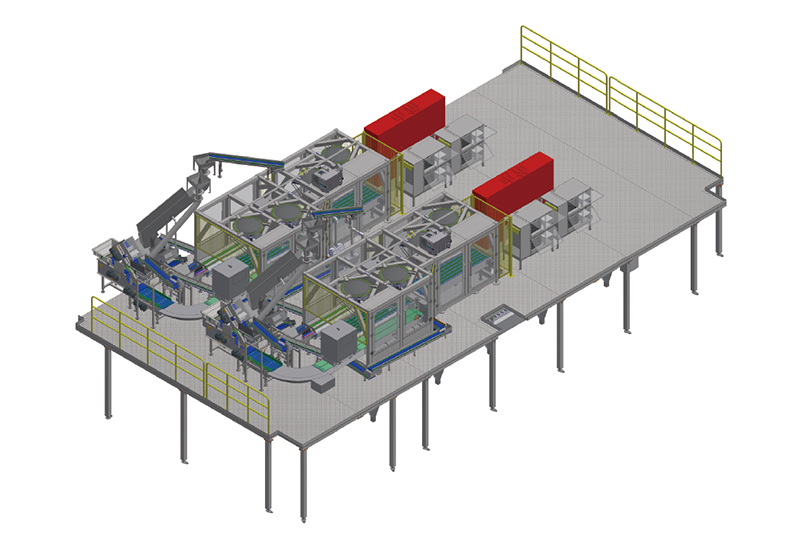

More video shows

- Wrap around case packing for aseptic juice pack

- Wrap around case packing for grouped beer bottle

- Wrap around case packing for milk bottle

- Wrap around case packing for filmed bottle pack

- Wrap around case packing for small bottle pack (two layers per case)

- Side infeed type wraparound case paker for tetra pack (milk carton)

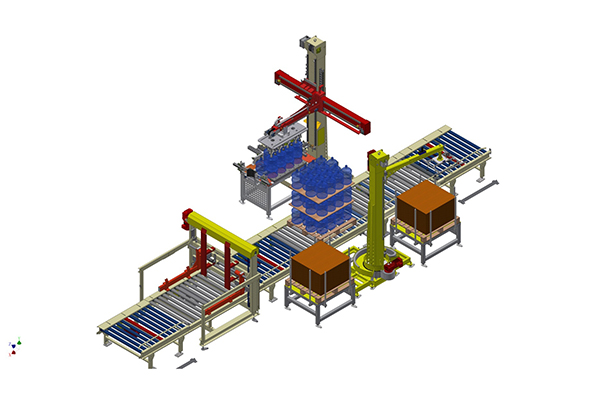

- Wraparound case packer for beverage cans

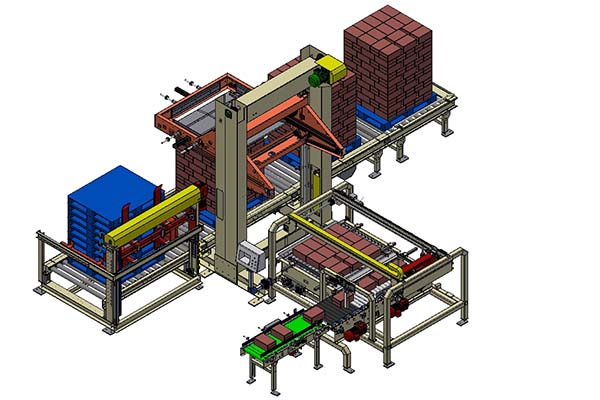

- Tray packer for beverage cans