High Quality 6000bph Qualified Juice Beverage Filling Machine/Production Line.

High Quality 6000bph Qualified Juice Beverage Filling Machine/Production Line.,

Juice Beverage Filling Machine,

Video Show

Hot Filling Lines

Hot filling technology can expand production and packaging opportunities for juices, nectars, soft drinks, isotonics, coffee and teas. No matter your beverage type, our expertise and technician team help you achieve more with extensive technical knowledge and packaging capabilities.

One-stop service for all your needs

A complete hot fill line solution from us lets you optimise performance and make more informed decisions across the lifetime of your line. With everything centred on one supplier, you get wide-ranging expertise, equipment and ongoing services to evaluate your entire project. This ensures high quality and efficiency from packaging to equipment, fast ramp-up and more.

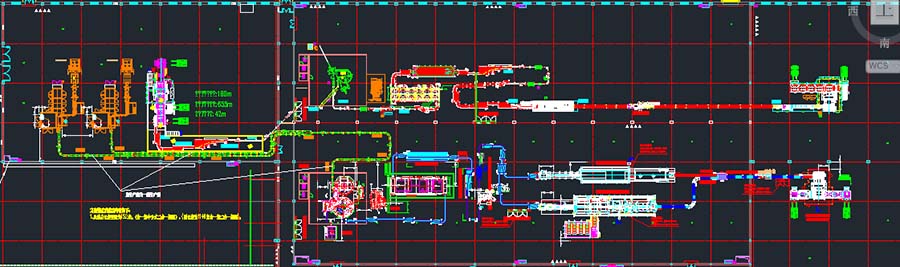

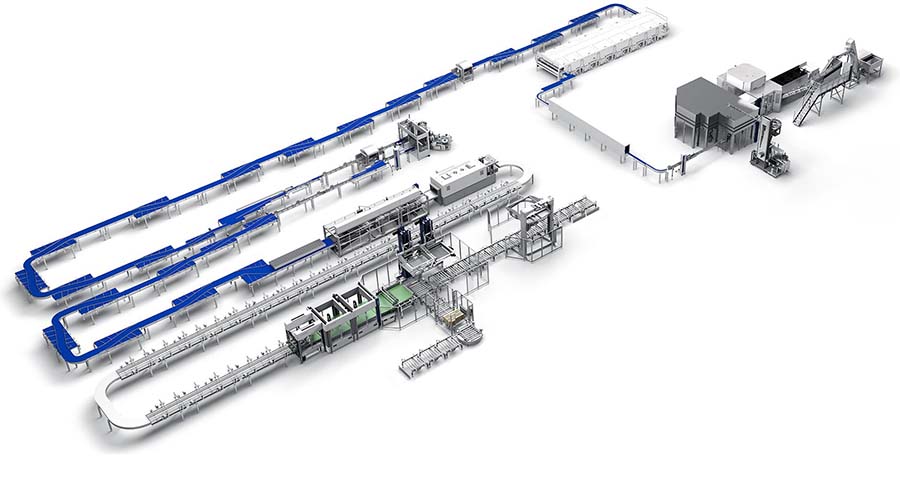

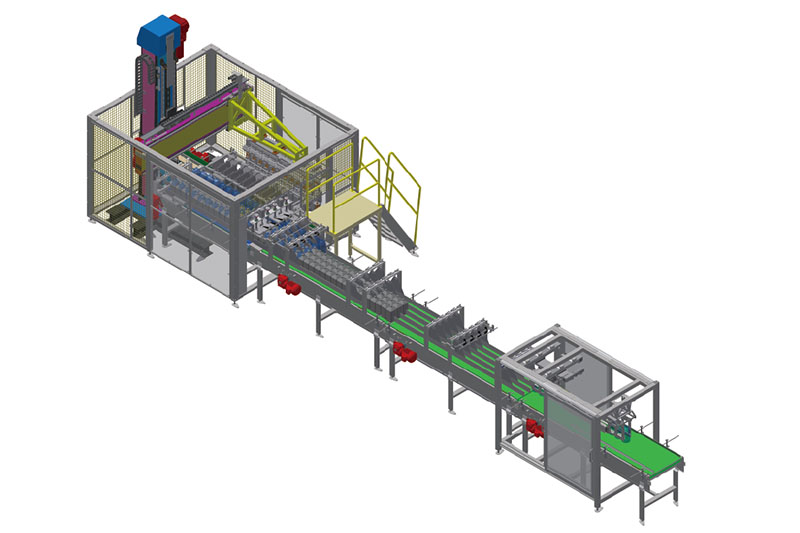

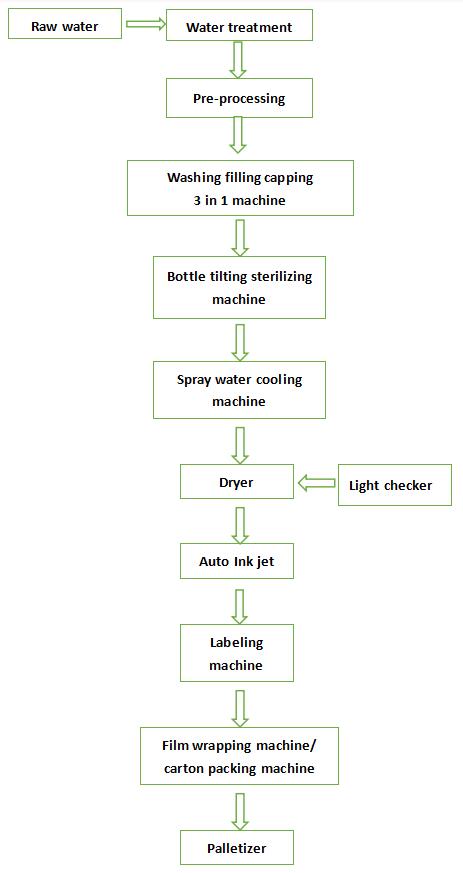

Automatic bottle beverage production line is composed of

1. bottle blow molding machine

2. air conveyor, 3 in 1 filling machine, (or combiblock machine)

3. bottle conveyor and light checking

4. tilter chain

5. bottle cooling machine

6. bottle dryer and date coding machine

7. labeling machine (sleeve labeling machine, hot melt glue labeling machine, self-adhesive labeling machine, cold glue labeling machine)

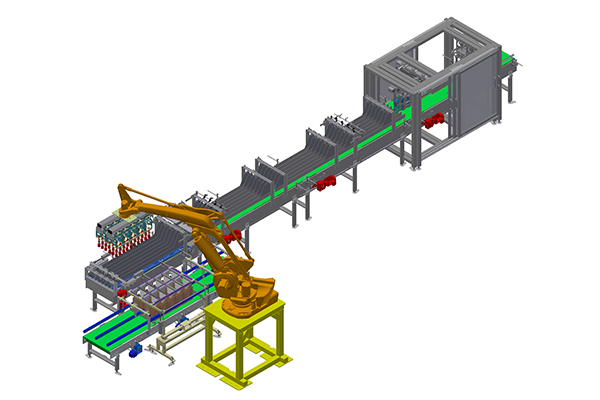

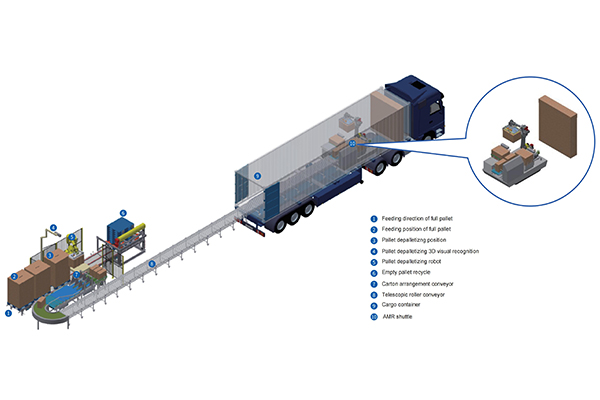

8. packing machine (shrink film wrapping packing machine, wraparound case packing machine, pick and place type case packer)

9. carton/ pack conveyor: roller conveyor or chain conveyor

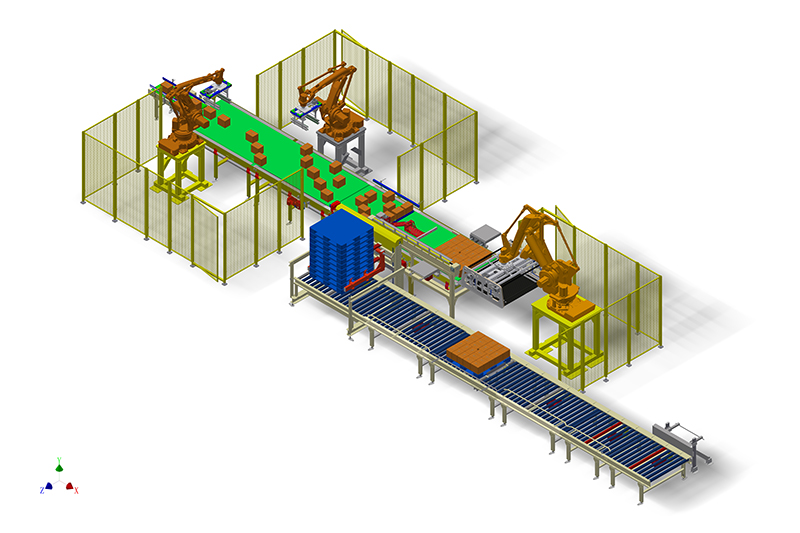

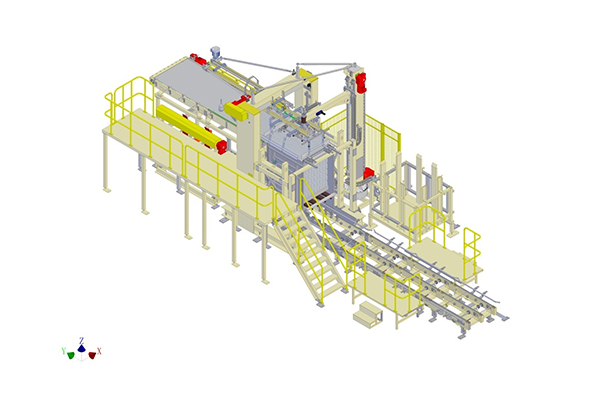

10. palletizer (low level gantry palletizer, high level gantry palletizer, single column palletizer)

11. stretch film wrapping machine

The filling line is typically a linkage production line made up of multiple stand-alone pieces of equipment with varying functions to meet the production or processing needs of a specific product.

It is an electromechanical device intended to reduce labor, optimize workflow, and boost production efficiency.