Low Level Empty Can/Bottle Depalletizer

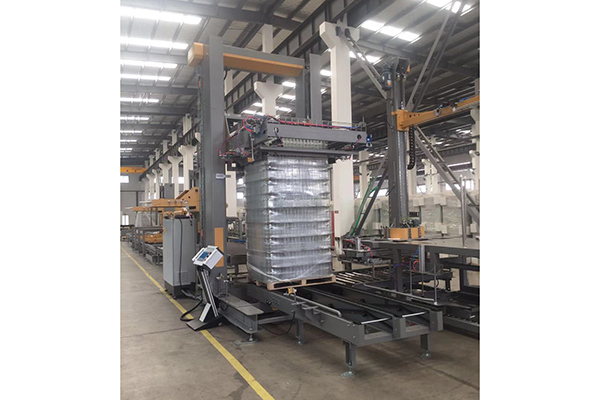

Working flow

Low level depalletizer working process is: Forklift put the full pallet on the chain conveyor, the chain conveyor will send the full pallet to the depalletizing working station; the lift platform will rise up to the top of the full pallet, the single column interlayer sucking mechanism takes out the interlayer paper from the pallet; the bottle clamp will grip the complete layer of bottles and move them to the lifting platform, the platform will fall down, the clamp move the complete layer of bottles from lift platform to the bottles conveyor, repeat the actions until all the bottles of pallet are moved to the can conveyor, and then the empty pallet will be sent to the pallet magazine.

Main Parameters

● Max Speed 36000 cans/bottles/h

● Max weight/layer 180Kg

● Max weight/pallet 1200Kg

● Max height of pallet 1800mm(standard type)

● Power 18.5Kw

● Air pressure 7bar

● Air consumption 800L/min

● Weight 8t

● The suitable pallet is adjustable: L1100-1200(mm), W1000-1100(mm), H130-180(mm)

Main configuration

|

Item |

Brand and supplier |

|

PLC |

Siemens(Germany) |

|

Frequency converter |

Danfoss (Demark) |

|

Photoelectric sensor |

SICK (Germany) |

|

Servo motor |

INOVANCE/Panasonic |

|

Servo driver |

INOVANCE/Panasonic |

|

Pneumatic components |

FESTO (Germany) |

|

Low-voltage apparatus |

Schneider(FRANCE) |

|

Touch screen |

Siemens (Germany) |

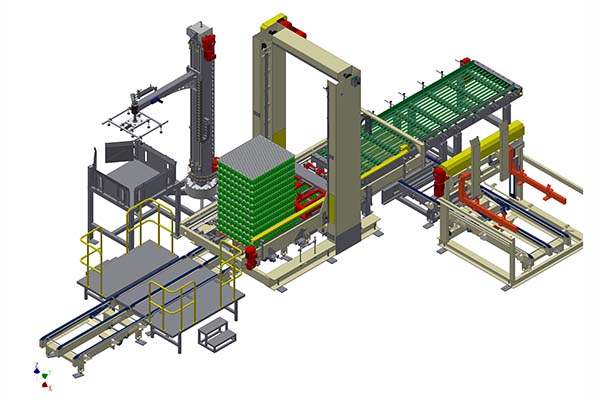

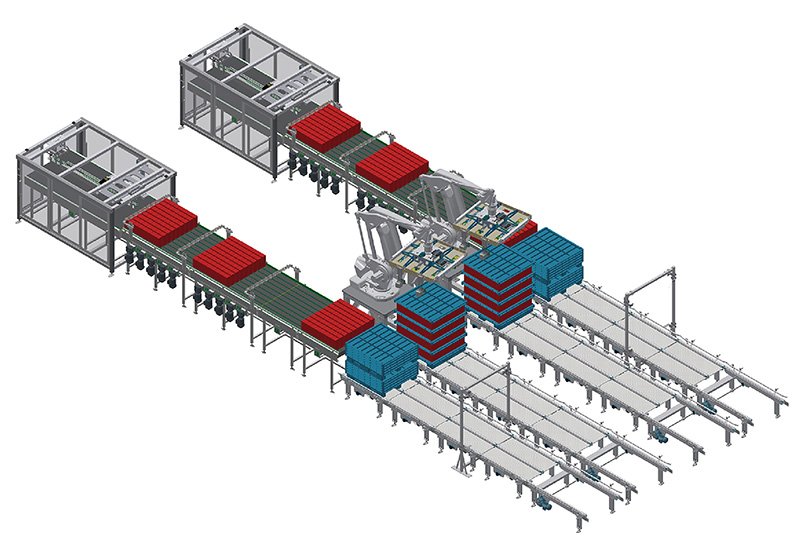

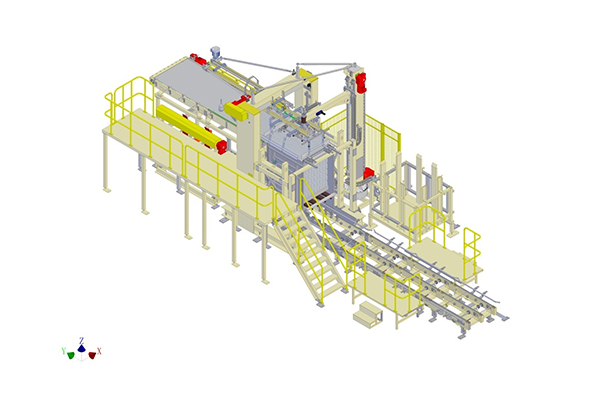

Layout

Layout Indication

More video shows

- Low level depalletizer for PET bottle FAT testing video in our factory

- Low level depalletizer machine for wine bottle in testing